An Unbiased View of DTF Transfers

An Unbiased View of DTF Transfers

Blog Article

The transfer procedure is carried out working with heat and pressure. Once the PET movie is positioned on to the fabric, the utilized heat and strain enable the ink to go through the PET film and onto the material.

overcome: The film made up of the powdered style ought to be heated next to activate the adhesive powder. This may be accomplished in the utilization of a heat push, curing oven, or conveyor dryer.

Pressing Your Transfers: All DTF transfers arrive prepared to press, so all you must do is abide by the application Directions for urgent on your clothes or merchandise. more info on urgent your transfers can be found further more in this FAQ.

Limited to CMYK colours: DTF printers trust in the CMYK coloration product and might only use four Key hues. Unlike regular printing strategies, you don't have the freedom to employ any coloration you motivation.

extend your horizons and examine new prospects in textile printing with our progressive DTF printers.

sturdiness: DTF transfers are noted for their toughness immediately after multiple washes, a crucial variable highlighted inside the “FAQs.”

By executing the printing techniques adequately and listening to the small print even though utilizing your DTF transfer printer, you could realize high-high-quality success.

While hugely tough, some peeling may well manifest over time, but cracking is generally not a challenge in comparison to a printing approach such as screen printing.

This checklist wouldn't be total without the Sleeve. such as remaining upper body or Collar, reserve this print placement for more simplified artwork. And like the other placements, the scale and placement must rely upon your specific brand or style and design. normally, sleeve prints appear much better at small sizing.

right before we dive into the main advantages of DTF heat transfers, Allow’s initially determine what they are. DTF warmth transfers undoubtedly are a type of warmth transfer technological know-how that permits you to print higher-high-quality, total-color patterns directly onto a transfer film, which may then be heat pressed on to a garment.

Yellowing of adhesive or waffle texture to the carrier can be done and standard; this will likely not affect software.

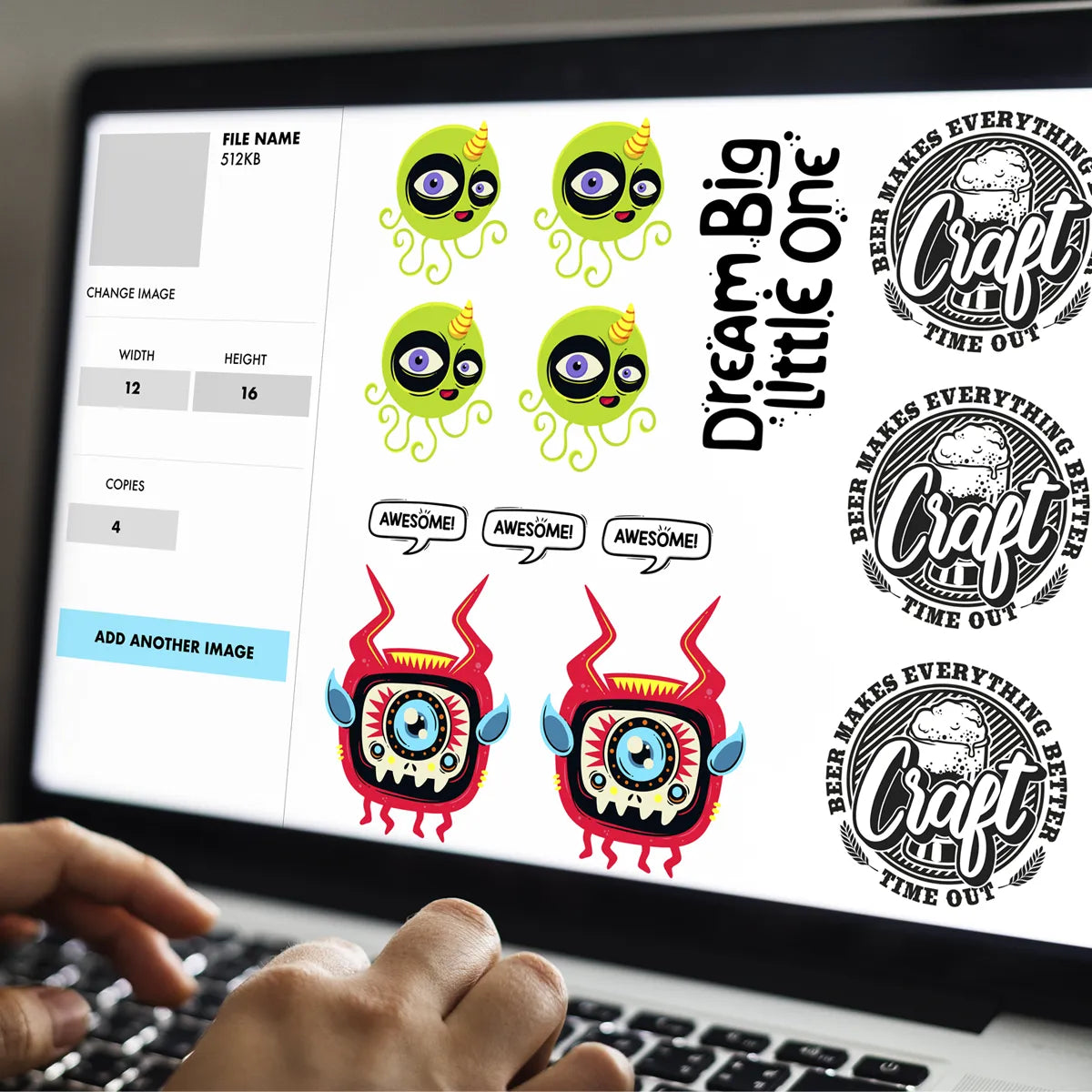

add: upcoming, you might add your style; choose the suitable transfer sheet size and also printed style size in inches (if a specific design and style dimension is required); point out the amount of transfers essential; and specify your garment sort/coloration. if you want an exact reorder, please let's understand that in addition.

DTF printer that prints the look on to a transfer sheet. This sheet is then prepared to press on to a garment utilizing heat and pressure, usually having a warmth press device .

no matter whether you are new towards the STAR software or thinking of a change into the STAR credit history, review our resources for read more a complete overview.

Report this page